Industrial IoT Gateway

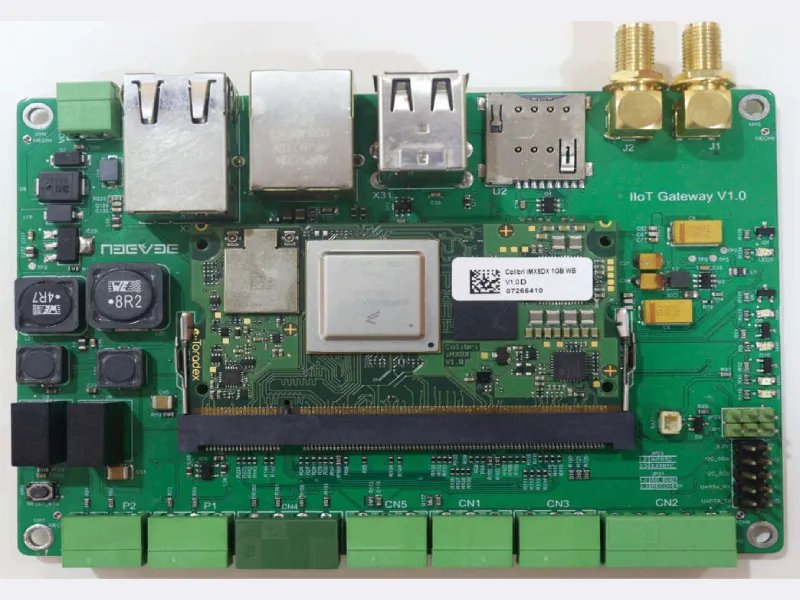

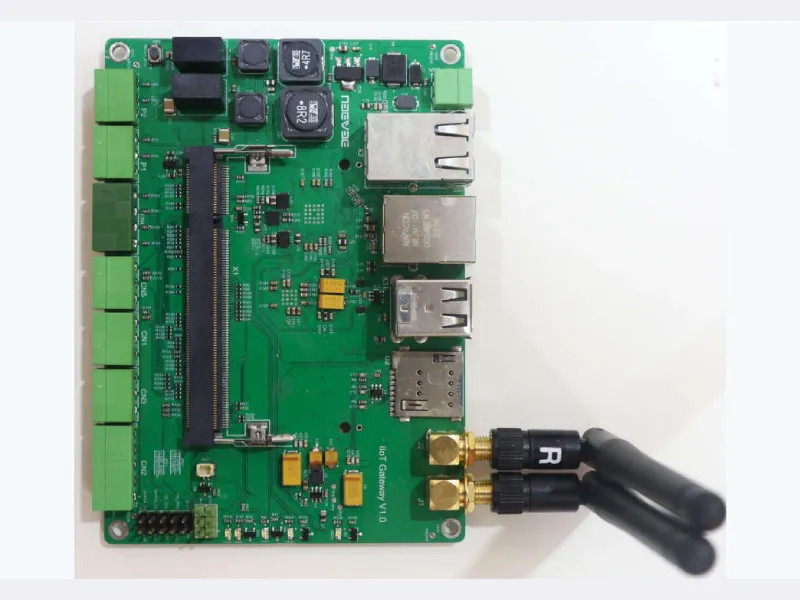

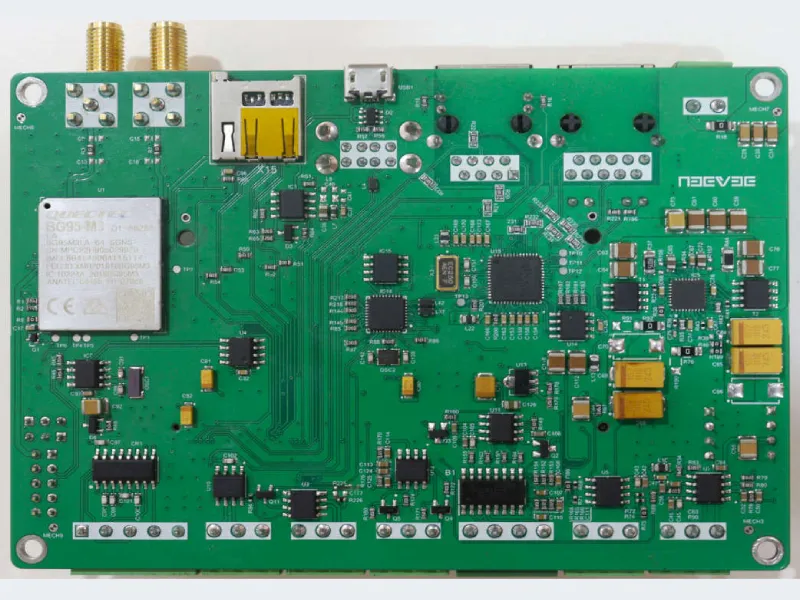

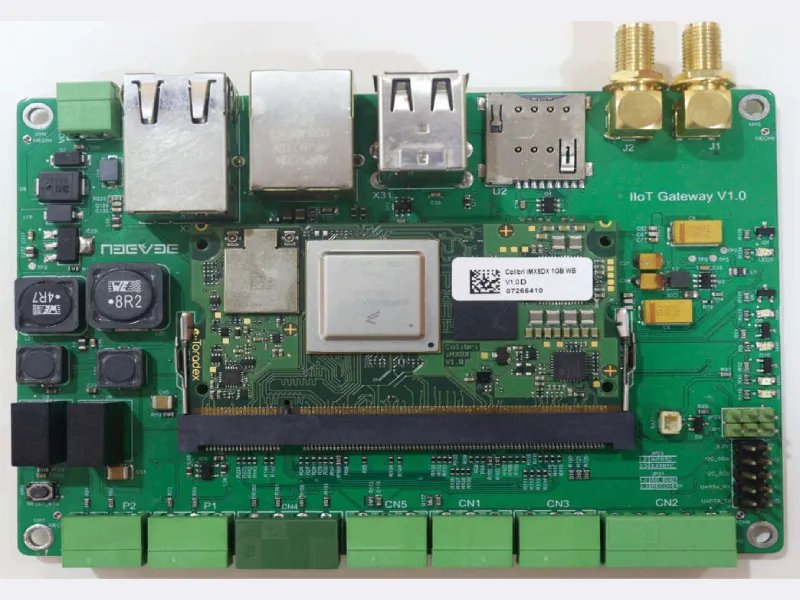

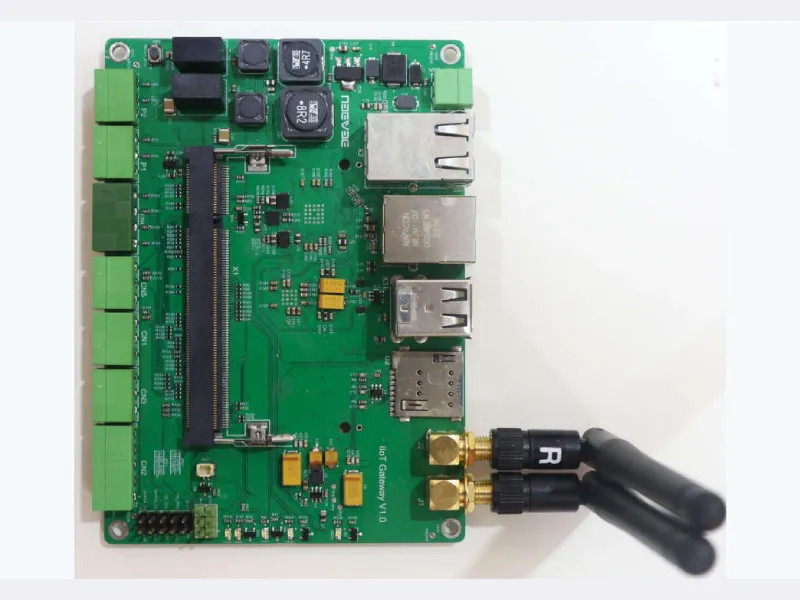

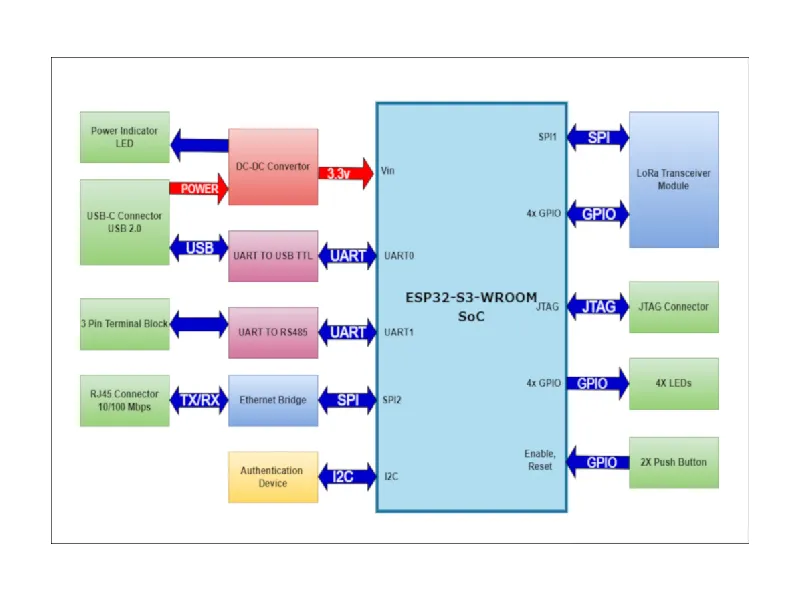

Our IIoT Gateway is engineered for seamless integration into Industry 4.0 / 5.0 and industrial automation ecosystems. It offers versatile interface options to meet the diverse connectivity demands of modern industrial environments.

Built to adapt—our gateway is highly customizable, with white-label deployment options to match client-specific requirements.

Powered by an Arm Cortex-A7 processor and Embedded Linux for dependable performance and easy upgradability.

Leverages the Yocto Project to provide a flexible framework for building tailored Linux distributions aligned with your IIoT application needs.

Ensures secure connectivity with major IoT cloud platforms, enabling reliable data exchange and remote management

4.9

Trustscore

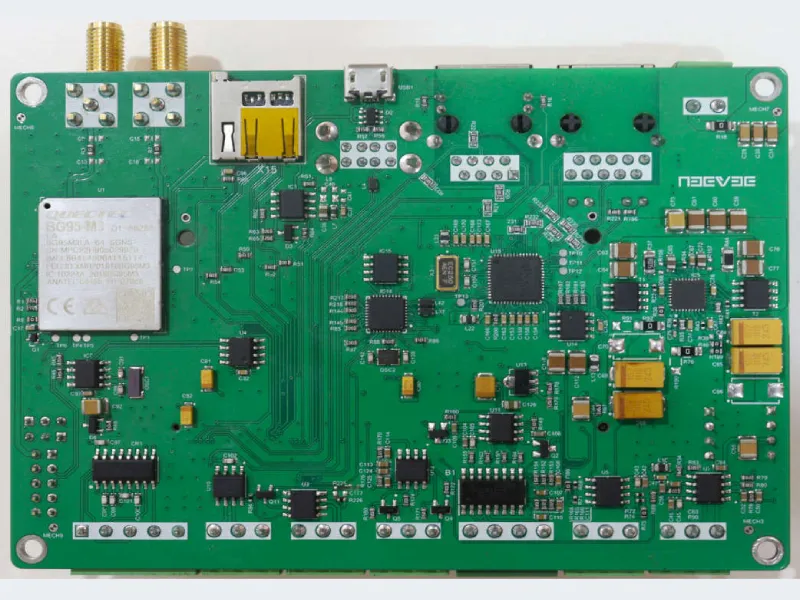

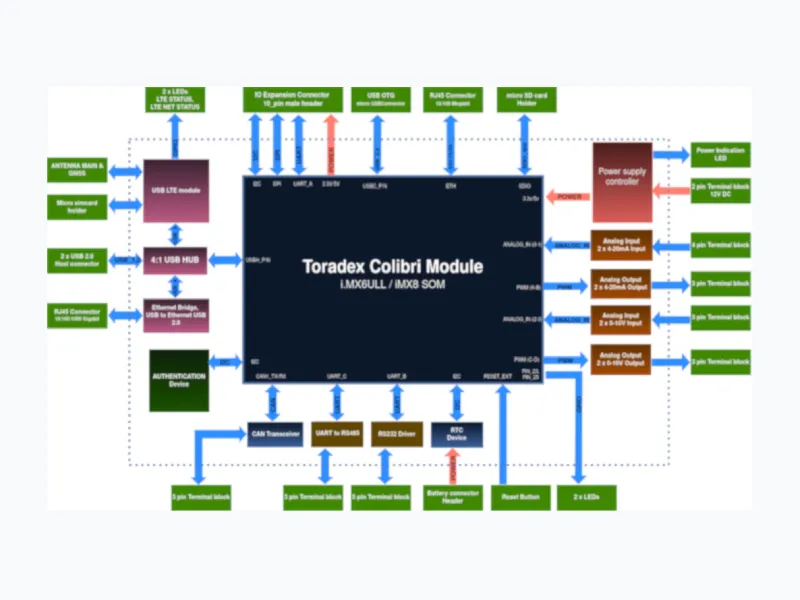

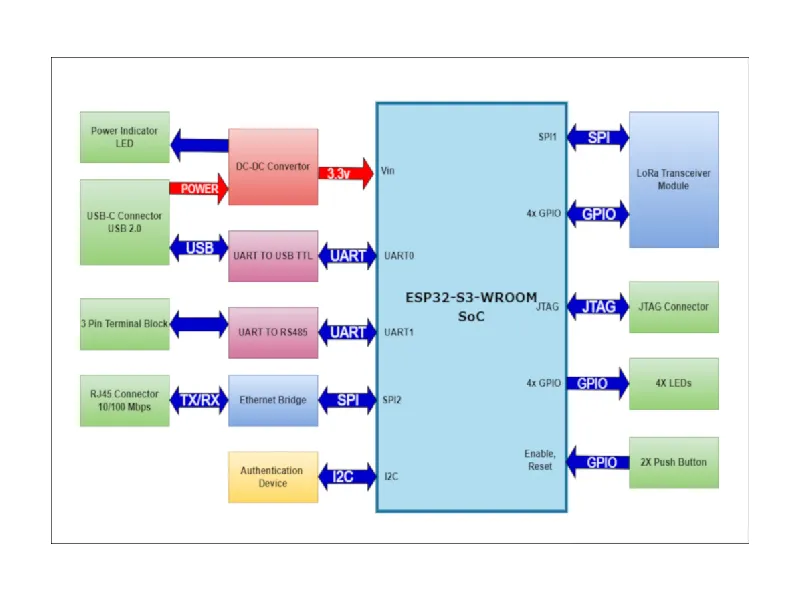

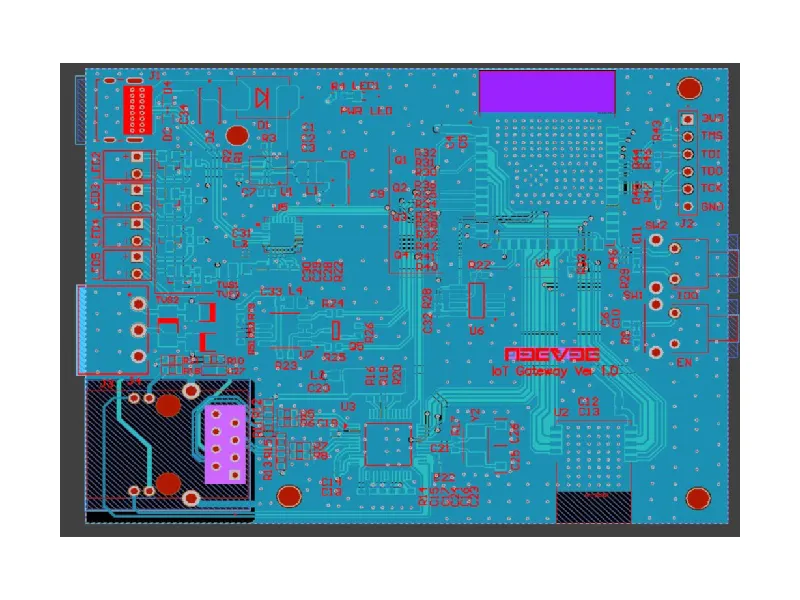

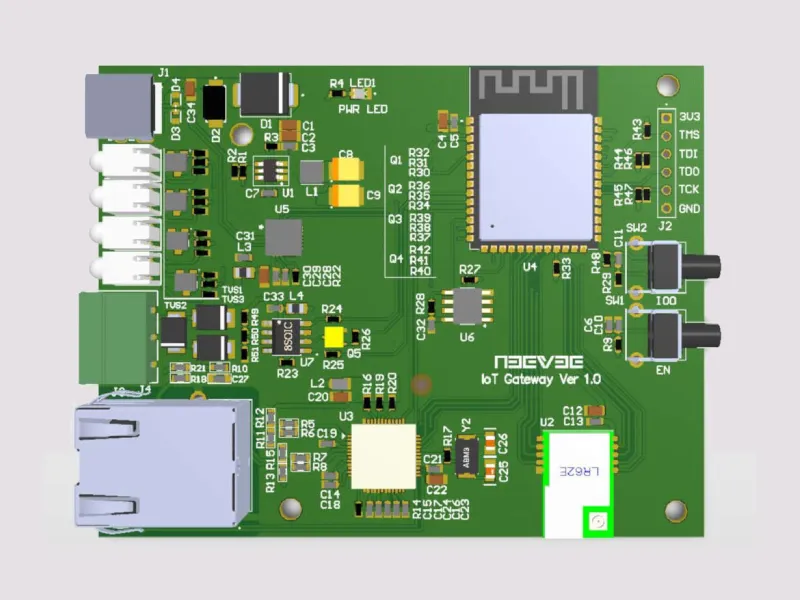

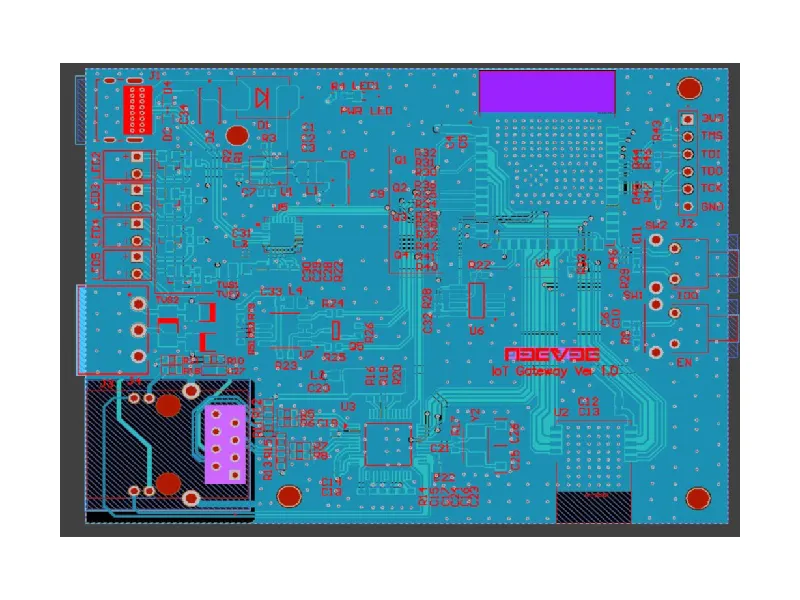

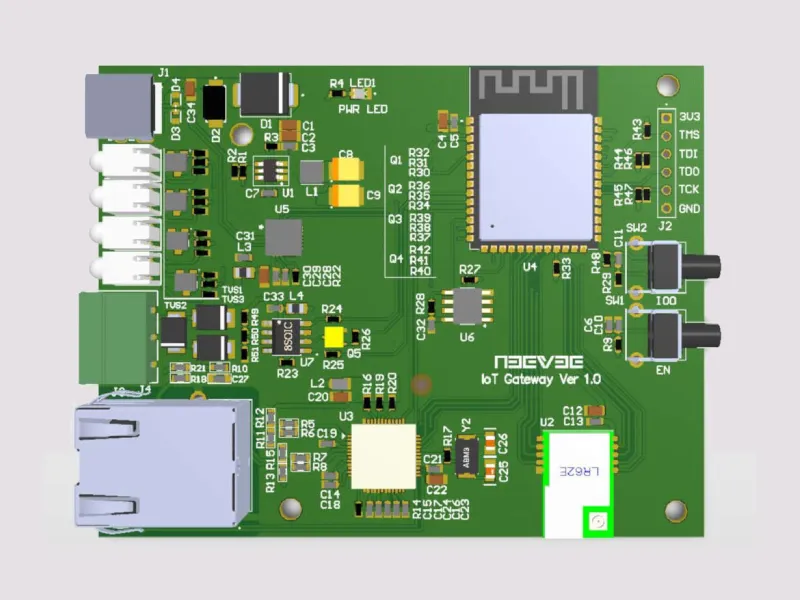

IIoT Gateway Specification

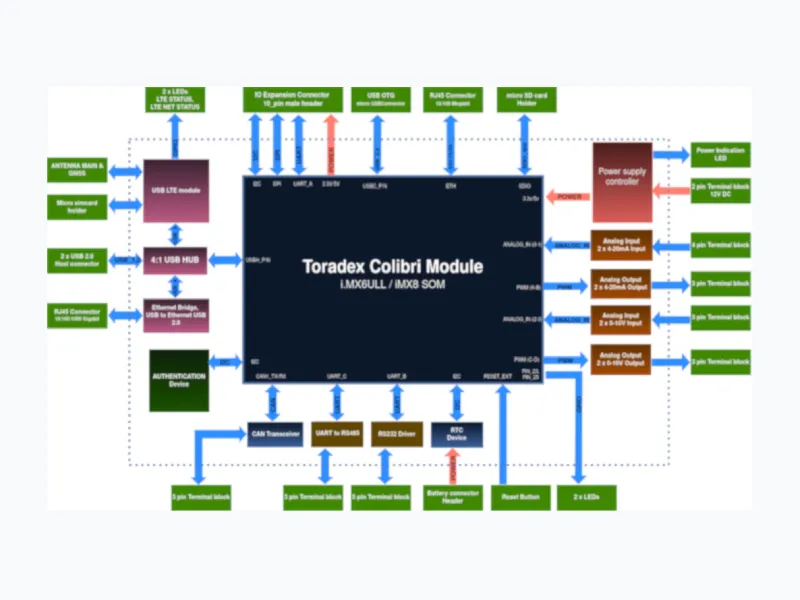

Tailored for edge gateway compute needs, offering flexible choices from a Single-Core ARM Cortex-A7 to a Dual-Core ARM Cortex-A35 processor with extensive customization support.

Equipped with 1 GB DDR memory and 4 GB eMMC storage, along with a Micro SD card slot supporting up to 128

GB—ideal for scalable user data storage needs.

Features dual Ethernet ports—one supporting 10/100 Mbps with IEEE 1588, and another supporting 10/100/1000 Mbps Gigabit Ethernet compliant with IEEE 802.3ab—alongside dual USB Host ports and a USB OTG port for versatile peripheral integration.

Fully equipped with essential industrial connectivity options, including RS-485 and RS-232 serial interfaces with Modbus-RTU support, and CAN Bus for robust field-level communication.

Includes 2 x 4–20 mA inputs and 2 x 4–20 mA outputs, along with 2 x 0–10 V inputs and 2 x 0–10 V outputs—enabling seamless integration with a wide range of industrial analog sensors and actuators.

Application Use Cases

- Interface the Gateway with CNC machines, injection molding machines, or hydraulic presses via:

- 4-20mA/0-10V (motor current, pressure, temperature)

- RS485/RS232 (PLC data extraction)

- CAN bus (automotive/industrial machine diagnostics)

- Utilizes AWS IoT Core for real-time telemetry streaming, AWS Lambda for serverless anomaly detection, and Amazon Lookout for Equipment to deliver predictive failure alerts—enabling proactive maintenance and operational efficiency.

- 30% reduction in unplanned downtime

- Predictive maintenance instead of reactive fixes

- Implementation

- Supports connectivity with energy meters via RS-485 Modbus and current sensors via 4–20 mA inputs to track machine power consumption. Integrated with AWS IoT Analytics to detect energy inefficiencies such as idle machine operation and optimize power usage.

- Impact

- Achieve 15–20% reduction in energy costs while lowering carbon footprint—supporting sustainability initiatives in line with Industry 5.0 goals.

- Implementation

- Leverages both CAN and RS-485 interfaces to establish a reliable, low-latency wired industrial mesh network—ideal for robust field-level communication in harsh environments. Integrated with AWS IoT Analytics to detect energy inefficiencies such as idle machine operation and optimize power usage.

- Impact

- Ensures robust communication even in electrically noisy environments—ideal for rugged MSME manufacturing plants where wireless connectivity may be unreliable.